Overview

Design Features

Contractor Benefits

Customer Benefits

TransCritical CO2 Packaged System

A natural refrigerant-based refrigeration system that is safe, sustainable and energy efficient in all climates.

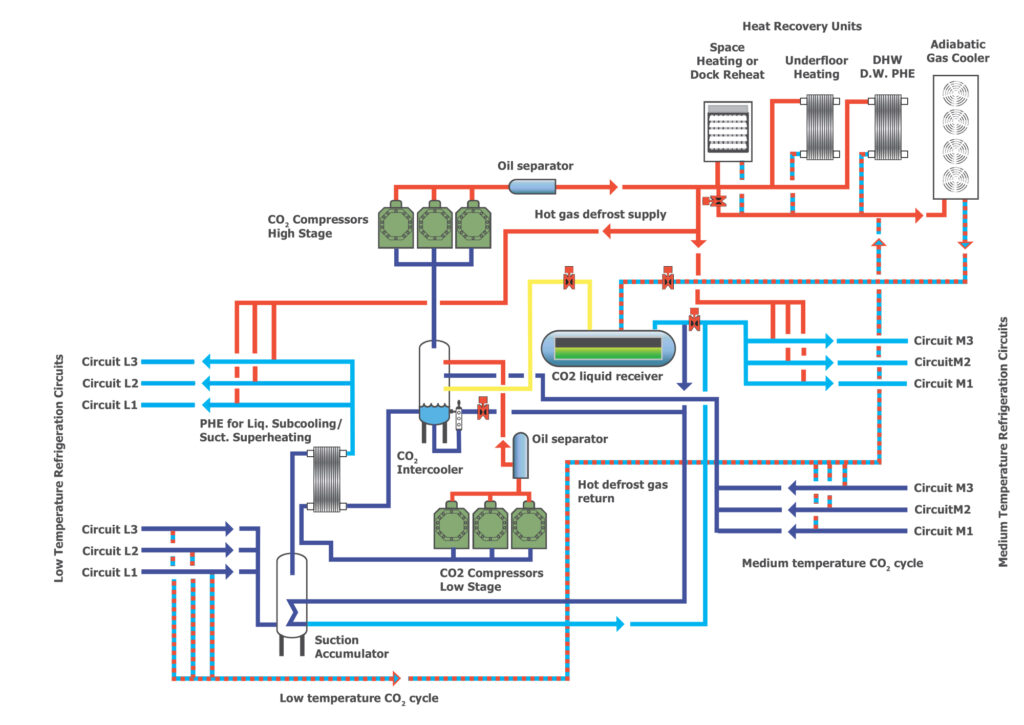

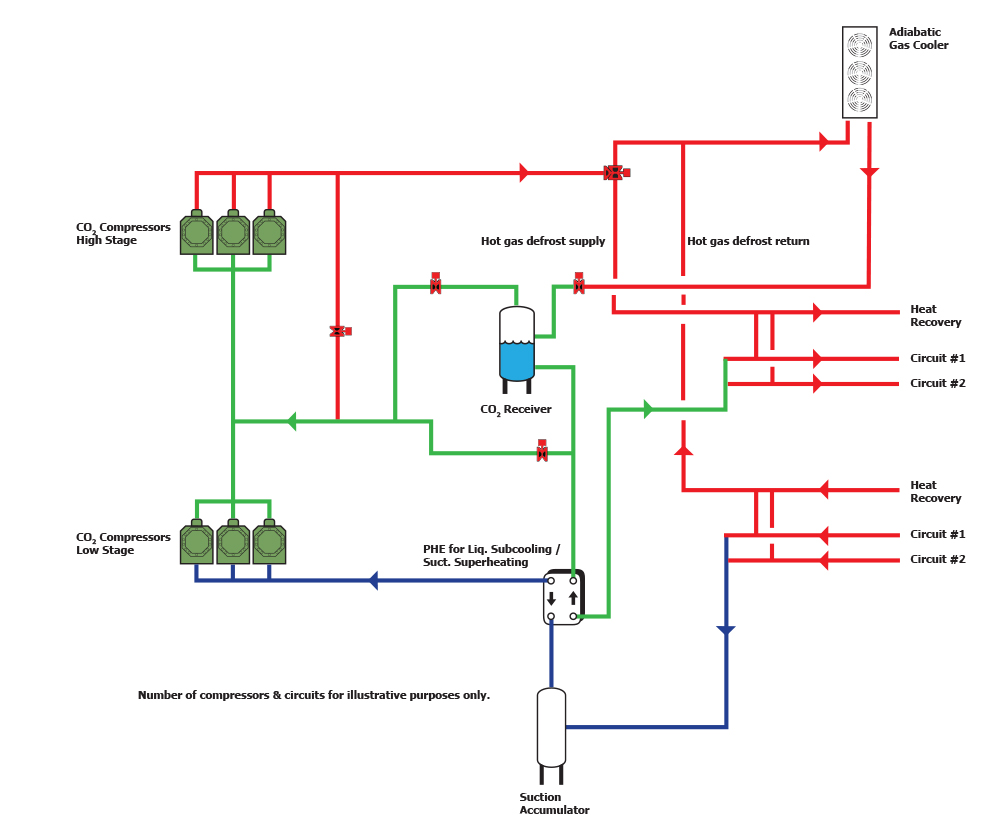

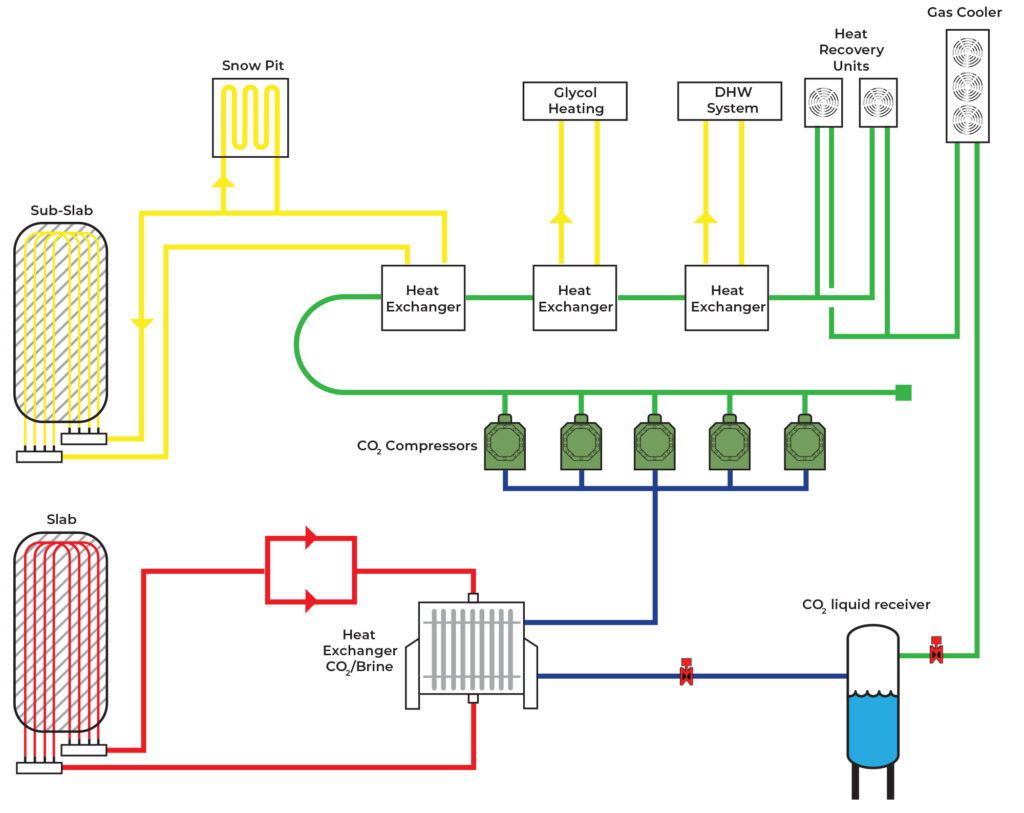

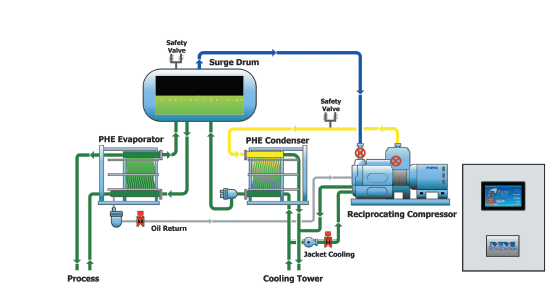

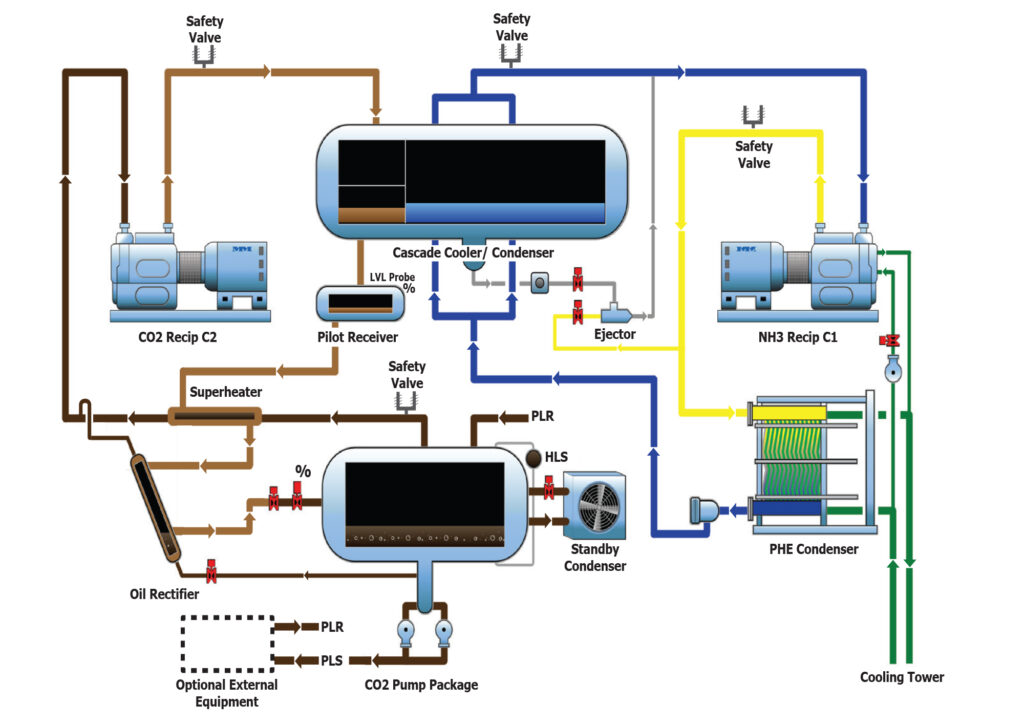

System Diagram- High pressure design eliminates a need for back-up generator and synthetic condensing unit during off-cycle

- High efficiency oil management system with multiple coalescing oil separators

- Microprocessor-based control system with supervisory HMI and cloud-based loT access

- Cooling capacities from 50 to 450 tons at -45 to 72 ºF room temperatures

- Single point power connection

- Insulated vessels and cold piping

- Power distribution to gas cooler and evaporators

- Full access doors for commissioning, start-up and service

- Regulatory cost and burden are significantly reduced

- Reduced energy cost by:

- Operating at higher suction temperatures

- Floating head pressure to 50 ºF

- Eliminating refrigerant and cooling water pump energy

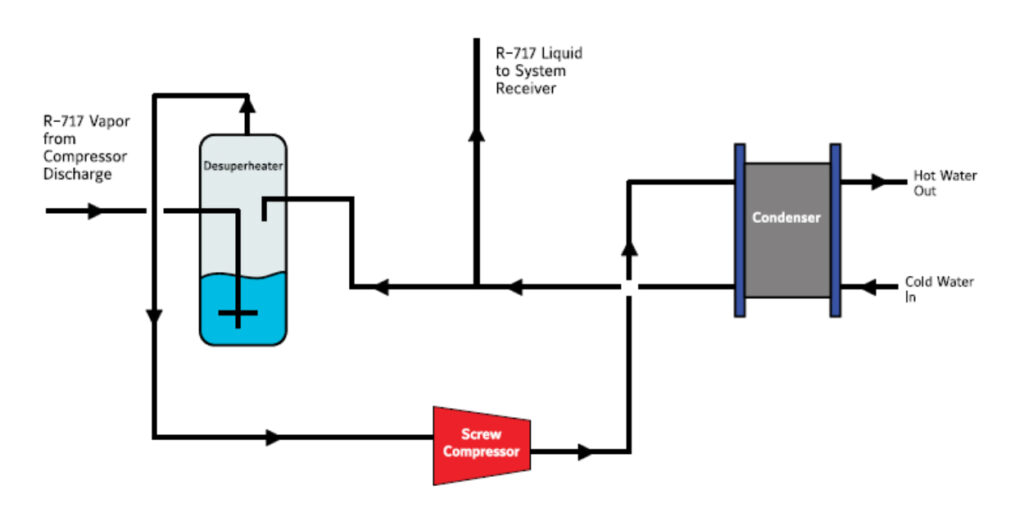

- Utilizing intelligent and efficient heat recovery

- Eliminating parasitic loads associated with air purgers, oil pots, and chemical feed pumps

- Reduced cooling water usage of up to 90% based on climate zone

- Significant reduction in maintenance cost:

- No water treatment

- No sewer cost

- Semi-Hermetic compressors do not require inspections for shaft seal replacements

- Direct drive ECM fans eliminate the need for belt drive maintenance